Understanding the LSM6DSLTR and Common Issues

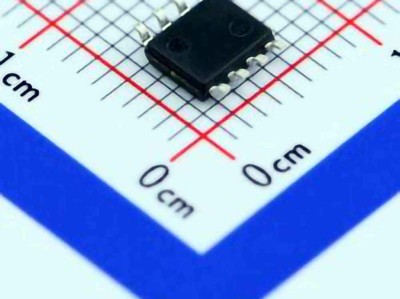

The LSM6DSLTR is a highly popular 6-axis Sensor from STMicroelectronics, widely used for motion tracking in devices such as smartphones, wearables, drones, and IoT devices. This sensor integrates a 3-axis accelerometer and a 3-axis gyroscope, making it a Power ful tool for detecting and measuring movement and orientation. While the LSM6DSLTR is designed to be highly reliable, it is not immune to problems that can hinder its performance. In this article, we will explore some common troubleshooting scenarios and solutions to ensure smooth operation.

1. Problem: Sensor Not Responding or Not Detected

One of the most frustrating issues that users face with the LSM6DSLTR is when the sensor is not detected by the microcontroller or when the sensor fails to respond to requests.

Possible Causes:

Incorrect I2C or SPI configuration.

Power supply issues, such as insufficient voltage or unstable current.

Physical connection issues like loose wires or bad solder joints.

Faulty sensor.

Solutions:

Check Power Supply: Ensure that the LSM6DSLTR is receiving the correct supply voltage. The sensor operates on a 1.8V to 3.6V range, and any deviation from this could cause the sensor to malfunction or remain unresponsive.

Verify Communication Protocol: The LSM6DSLTR supports both I2C and SPI communication protocols. Ensure that the configuration for the chosen protocol is correctly set up on both the microcontroller and the sensor. Double-check the wiring for I2C (SDA, SCL) or SPI (MISO, MOSI, SCK, CS) connections to ensure proper connectivity.

Use Correct I2C/SPI Address: For I2C communication, ensure you are using the correct I2C address. The default I2C address for the LSM6DSLTR is 0x6A for the standard version or 0x6B for the alternate address.

Inspect Physical Connections: If you're working with a breakout board, ensure that the sensor is properly connected to the microcontroller. Inspect the solder joints and cables for possible loose connections. Poor physical connections can lead to intermittent or no communication with the sensor.

Check Sensor Initialization: Make sure that the initialization sequence for the LSM6DSLTR is being followed correctly in the software. This includes configuring the sensor’s power mode, data output rate (ODR), and any other required parameters.

2. Problem: Incorrect Sensor Data or Calibration Issues

Another common issue with the LSM6DSLTR is when the sensor provides inaccurate or noisy data, especially for applications requiring precise motion tracking.

Possible Causes:

Uncalibrated accelerometer or gyroscope.

Misconfigured sensor settings.

Environmental factors such as vibration or temperature changes.

Solutions:

Calibrate the Sensor: Both the accelerometer and gyroscope in the LSM6DSLTR require calibration for optimal performance. If the sensor’s raw data seems inconsistent or incorrect, you may need to calibrate it. This can involve:

Accelerometer Calibration: To calibrate the accelerometer, ensure that the device is placed on a stable, level surface and measure the raw accelerometer data. Apply appropriate offsets for each axis to account for sensor biases.

Gyroscope Calibration: Gyroscopes need to be calibrated to account for any initial angular velocity bias. A static environment, where no movement occurs, can be used to determine the gyroscope’s drift and compensate accordingly.

Check Output Data Rate (ODR): Ensure that the output data rate (ODR) is configured according to the needs of your application. Setting the ODR too high can cause excessive noise, while setting it too low can lead to slower response times.

Filter the Data: If the data appears noisy, consider using digital filters to smooth the accelerometer and gyroscope readings. The LSM6DSLTR offers built-in low-pass filters that can be applied to reduce high-frequency noise.

Consider Environmental Factors: If the sensor is used in environments with heavy vibration, rapid temperature changes, or magnetic interference, these factors can negatively impact sensor readings. Try to isolate the sensor from such environmental influences as much as possible.

3. Problem: Sensor Draining Too Much Power

In battery-powered applications like wearables or IoT devices, power consumption is a critical factor. If the LSM6DSLTR is drawing excessive power, it can shorten the device’s battery life and cause other performance issues.

Possible Causes:

The sensor is operating in high-power modes unnecessarily.

Incorrect power management settings in the software.

Sensor not entering low-power states when idle.

Solutions:

Use Low Power Modes: The LSM6DSLTR offers several power modes that can help reduce power consumption. For instance, you can put the sensor in a low-power mode (like the “low-power” accelerometer mode) when full performance is not required. Similarly, the sensor can be put into sleep mode when it’s not actively measuring motion.

Configure Output Data Rate (ODR) Wisely: A lower ODR reduces both power consumption and data bandwidth. If you do not need high-frequency updates, set a lower ODR to save power. For example, reducing the data output rate from 1kHz to 100Hz can significantly reduce power consumption.

Optimize the Communication Protocol: If you're using I2C, ensure that the communication frequency is kept as low as possible. Continuous communication with the sensor can also contribute to higher power consumption. If possible, switch to SPI for faster, more efficient data transfer.

4. Problem: Inaccurate Orientation or Motion Tracking

For applications that rely on precise motion or orientation data (such as gesture recognition or navigation), inaccurate readings from the LSM6DSLTR can lead to erroneous results, affecting the performance of the entire system.

Possible Causes:

Lack of proper calibration.

Sensor misalignment.

Incorrect use of sensor fusion algorithms.

Solutions:

Sensor Alignment: Ensure that the sensor is properly oriented relative to the application. If you're using the sensor in a wearable device or a robot, confirm that the axes of the accelerometer and gyroscope are aligned with the intended direction of movement.

Use Sensor Fusion Algorithms: For accurate orientation tracking, use sensor fusion algorithms like a Kalman filter or complementary filter to combine the accelerometer and gyroscope data. These algorithms can help reduce the noise in raw sensor data and improve the overall accuracy of motion tracking.

Regularly Recalibrate the Sensor: As external conditions (like temperature or humidity) change, recalibration may be necessary to maintain sensor accuracy.

Advanced Troubleshooting for LSM6DSLTR Performance Optimization

In this section, we will dive deeper into advanced troubleshooting methods and solutions for optimizing the performance of your LSM6DSLTR sensor.

5. Problem: Communication Timeouts or Data Loss

In some cases, users experience communication timeouts or data loss when interfacing with the LSM6DSLTR. This can lead to missed measurements and unreliable performance.

Possible Causes:

High bus traffic on I2C or SPI.

Improper handling of interrupt signals.

Timing issues in the software.

Solutions:

Reduce I2C Bus Traffic: If the I2C bus is congested due to other peripherals, the LSM6DSLTR may not respond in a timely manner. Try reducing the frequency of other I2C transactions or use a dedicated bus for the sensor to improve reliability.

Handle Interrupts Properly: The LSM6DSLTR supports interrupts for motion detection, data ready signals, and more. Ensure that the interrupt pins are correctly connected and that the interrupt service routines (ISRs) are optimized to avoid delays in processing.

Use DMA for SPI Transfers: If using SPI, consider implementing Direct Memory Access (DMA) for data transfers to reduce CPU overhead and prevent data loss. DMA can ensure smoother data handling, especially when working with large datasets or high-frequency data.

6. Problem: Sensor Performance Degradation Over Time

Over time, some users may notice that the performance of the LSM6DSLTR sensor degrades, leading to inconsistent or noisy data.

Possible Causes:

Aging or wear of the sensor components.

Long-term exposure to extreme conditions (e.g., high temperature, humidity, or physical stress).

Accumulation of errors or drift in calibration.

Solutions:

Regular Calibration: To counteract drift and aging, perform periodic recalibration of the accelerometer and gyroscope, especially if the sensor is being used in a high-precision application.

Environmental Considerations: Protect the sensor from extreme conditions such as high temperatures, moisture, and mechanical stress that can lead to long-term degradation. Consider using protective enclosures or coatings for the sensor.

Use Advanced Sensor Fusion: To mitigate long-term drift and errors, employ advanced sensor fusion algorithms that continuously adjust and correct for sensor inaccuracies over time.

By addressing these common troubleshooting scenarios and implementing the suggested solutions, you can significantly enhance the performance and reliability of your LSM6DSLTR sensor. With careful configuration, proper calibration, and attention to power management, the LSM6DSLTR can continue to serve as a robust motion-sensing solution for a wide range of applications.

Partnering with an electronic components supplier sets your team up for success, ensuring the design, production, and procurement processes are quality and error-free.